we have developed high-quality, user-friendly, and cost-effective thermal technology during this time period. We are the primary distributors and exporters of all Grasso air conditioner compressors. We have a dedicated team of professionals with extensive experience in the Refrigeration Compressors and compressor Spare Parts industry.

RC 6 SERIES

With the RC6, Grasso offers a new line of open reciprocating compressors with a number of specialized properties. In addition to innovative thinking in the field of compressor technology, these characteristics are also the result of the most advanced computer technology (CAE/CAM systems). In developing this new compressor, Grasso also utilized its extensive expertise in energy-saving techniques. Consequently, the new series of Grasso RC6 compressors represents the cutting edge of modern compressor technology. The RC6 compressors are significantly smaller than other comparable compressors, resulting in significant space savings.

Universal application

The Grasso RO6 compressor is ideally suited for use in refrigeration and freezing systems, in addition to heat pumps and air conditioning units.

Suitable for all halocarbon refrigerants

The Grasso RC6 compressor is compatible with all commonly used halocarbon refrigerants, such as R12, R22, R502, and R13B1.

Operating temperature range from -80°C to +-80°C

The Grasso RCE compressor has a maximum discharge pressure of 26 bar, allowing it to operate from evaporating temperatures as low as -80°C (R13B1) to condensing temperatures as high as +80°C (R12).

Extra high refrigerating capacity

Because the Grasso RC6 compressor is designed to operate on R13B1, it is possible to achieve extremely high refrigeration capacities at low evaporating temperatures.

Wider choice of drive units

The fastest speed that the Grasso RC6 compressor can go is 1800 rev/min. Because of this, there is a significantly greater selection of drive units available.

15% more energy saving

The RC6 is constructed so that its relative power consumption is extremely low. The result is a 15% reduction in energy consumption and ongoing cost savings.

Very high dependability

The Grasso RC6 compressor is exceedingly dependable, thanks to its high-quality construction. Two factors account for this:

-

first its simple but ingenious design and

-

Second, the high quality of the materials used, with particular attention paid to the wear-prone areas. The RC6 compressor’s maintenance schedule has been drastically reduced. special tools are not required

RC 12E SERIES

The Grasso 12E series. A selection of open-type, reciprocating refrigeration compressors with exceptional dependability. All suitable for use with NH3, R404A, R507, R134a, R22, or any of the new alternative refrigerants, and designed to operate efficiently in virtually any industrial refrigeration installation for cooling or chilling applications.

The Grasso 12E series contains:

-

4 single-stage models

-

8 two-stage models with different LP/HP volume ratio‘s and LP swept volumes.

The Grasso 12E provides lower investment and maintenance costs per kilowatt cooling capacity. Utilizing new, innovative technologies in the design of the compressor allows for a better price-to-performance ratio. With composite material valves, lightweight pistons, and low-wear piston rings, this model of compressor can operate at velocities of up to 1,500 rpm. In conjunction with our exclusive welded steel compressor design, these innovative features enable us to provide you with complete dependability and maximum efficiency.

V SERIES

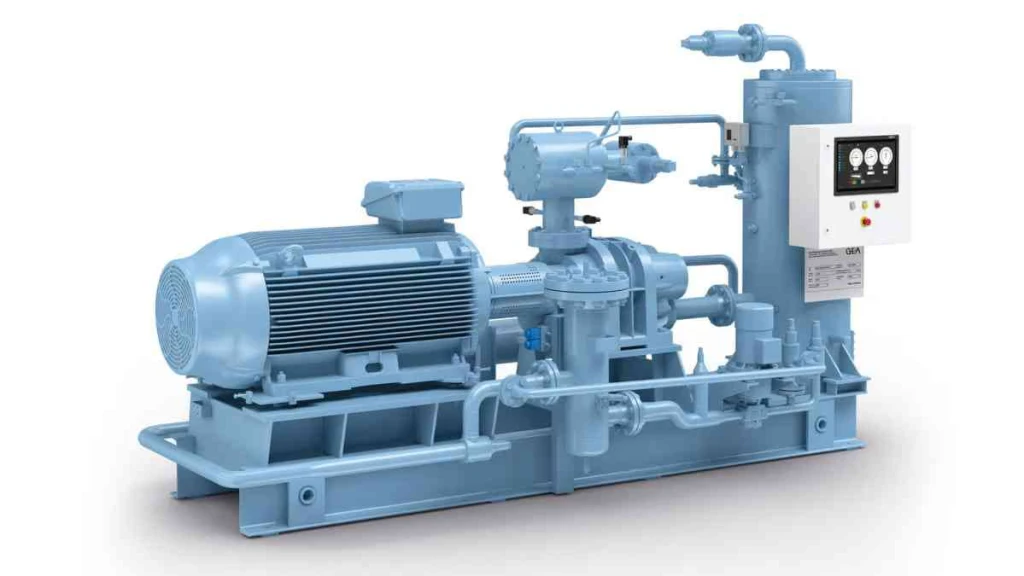

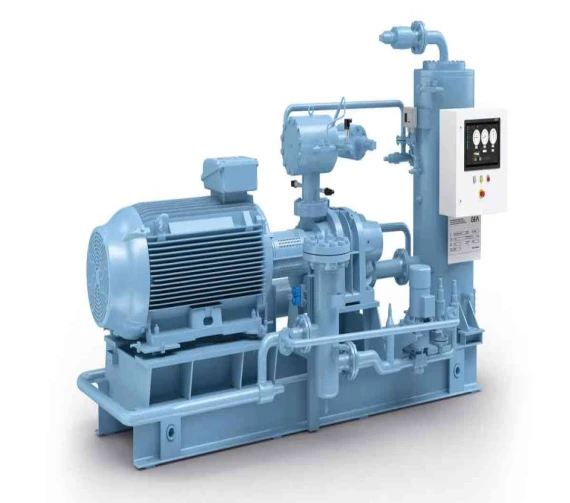

With the introduction of the GEA Grasso V reciprocating compressor series, GEA ushers in an entirely new era in the industrial refrigeration market. Throughout the development of the GEA Grasso V series, GEA places itself in the shoes of the end user. Every component was evaluated for the most essential factors that contribute to a low Total Cost of Ownership, such as energy consumption, maintenance, and minimal delay. The outcome is not only the most efficient reciprocating compressor on the market, but also a compressor with electronically controlled service intervals (extended and flexible) to reduce Total Cost of Ownership without compromising reliability. This GEA Grasso V includes a comprehensive single stage and two stage series with a swept volume range of 217 to 1,592 m3h.

Features of GEA Grasso V Series

-

Unique steel welded compressor housing

-

No water cooling required

-

Extended and flexible maintenance intervals

-

Maintenance monitor for indication of upcoming service intervals

-

Heavy duty axial roller bearing

-

Counter pressure independent overflow valve

-

Capacity control steps per cylinder

-

Suitable for speed control

-

Peek technology for high efficiency and long valve life time

-

Low noise level

-

Lowest Total Cost of Ownership (TCO)

-

Refrigerant: NH₃

|

Models |

Swept volume (m³/h) |

Cooling cap. (kW) NH₃ |

Dimensions (mm) |

Weight (kg) |

||

|

0/+40℃ |

L |

W |

H |

|||

|

Single Stage |

||||||

|

GEA Grasso V 300 |

290 |

237 |

882 |

933 |

922 |

575 |

|

GEA Grasso V 450 |

435 |

355 |

1076 |

933 |

922 |

751 |

|

GEA Grasso V 600 |

580 |

474 |

1363 |

933 |

922 |

1042 |

|

GEA Grasso V 700 |

637 |

549 |

1062 |

1076 |

1013 |

794 |

|

GEA Grasso V 1100 |

955 |

823 |

1306 |

1076 |

1013 |

1054 |

|

GEA Grasso V 1400 |

1274 |

1098 |

1666 |

1076 |

1027 |

1495 |

|

GEA Grasso V 1800 |

1592 |

1372 |

1909 |

1076 |

1027 |

1725 |

RC 9 SERIES

The Grasso RC9 series is a group of high-quality, fast, open-type reciprocating compressors for cooling systems. The series is made to work with ammonia, R22, R134a, R404A, and other new refrigerants in almost all types of industrial freezing and cooling systems. The RC9 series is also used by Grasso for their reciprocating chillers for ammonia-liquid.

The series comprises:

• 3 single-stage models with swept volumes of 140, 280 and 420 m*/h (83, 166 and

249 CFM) at 1450 min’.

• 2 two-stage models with LP swept volumes of 140 and 280 m°/h (83 and 166 CEM) at 1450 min.

RC 10 SERIES

A variety of reciprocating, open-type refrigeration compressors with exceptional dependability. The main idea behind their design is that they should be completely reliable in the worst situations, while also being cost-effective. The Grasso 10 series is made to work well in almost any kind of industrial refrigeration system for cooling or freezing.

Features of Grasso 10 series

-

Compressor casing made of welded steel

-

No cooling water necessary

-

Extensive variety of single-stage and two-stage models

-

Steps per cylinder for capacity control

-

Appropriate for speed regulation (600 – 1,500 min-1).

-

Composite material for high performance and extended valve life

RC 12 SERIES

The Grasso 12 series. A range of outstandingly reliable, open type, reciprocating refrigeration compressors. All designed to work efficiently in almost any type of industrial refrigeration installation for cooling or freezing applications and all suited to use NH3, R404A, R507, R134a, R22 or any of the new alternative refrigerants.

The Grasso 12 series contains the world’s largest number of compressors within one range:

-

4 single-stage models

-

8 two-stage models with different LP/HP volume ratio’s and LP swept volumes.

The Grasso 12 compressors have already proven themselves all over the world for many years in terms of reliability under the most demanding circumstances and with an alert eye to economics. Grasso has paid special attention to such aspects as maintenance costs and serviceability. The Grasso 12 series offers you maximum reliability for modest investment and maintenance costs. The Grasso 12 series is a typical example of Grasso’s unique welded steel compressor design. A design contributing to a large field of operation and lower installation cost without the need for additional water cooling circuits, especially in combination with ammonia (NH3).